CMC vs. GMP

In biotech and pharma, CMC and GMP get tossed around like they’re interchangeable. They’re not. One is the “what and how.” The other is the “rules you must follow while doing it.”

For business professionals, especially those in finance, legal, consulting, or commercial roles, understanding CMC vs. GMP is critical. This is where timelines slip, budgets balloon, and valuation risk hides.

We’ll break it down in this edition of The Primer, and if you want a deeper dive check out our CMC Primer and GMP Primer microcourses. Choose from the monthly Microcourse Subscription or use this coupon code: CMCGMP at check out for our “buy one get one” offer.

What and How

CMC stands for Chemistry, Manufacturing, and Controls. It’s the section of a regulatory submission (like an IND, NDA, or BLA) that explains:

- What the drug is

- How it’s made

- How it’s tested

- How you know it’s consistent

- How you control quality over time

If you’re submitting to the FDA, your CMC section answers one big question: Can this company reliably manufacture a safe, pure, and potent medication—every single time?

CMC includes:

- Drug substance (API) characterization

- Manufacturing process description

- Raw material controls

- Specifications and testing methods

- Stability data

- Container closure systems

- Comparability (if you change the process)

Think of CMC as the scientific and technical blueprint of your product.

Rules of the Road

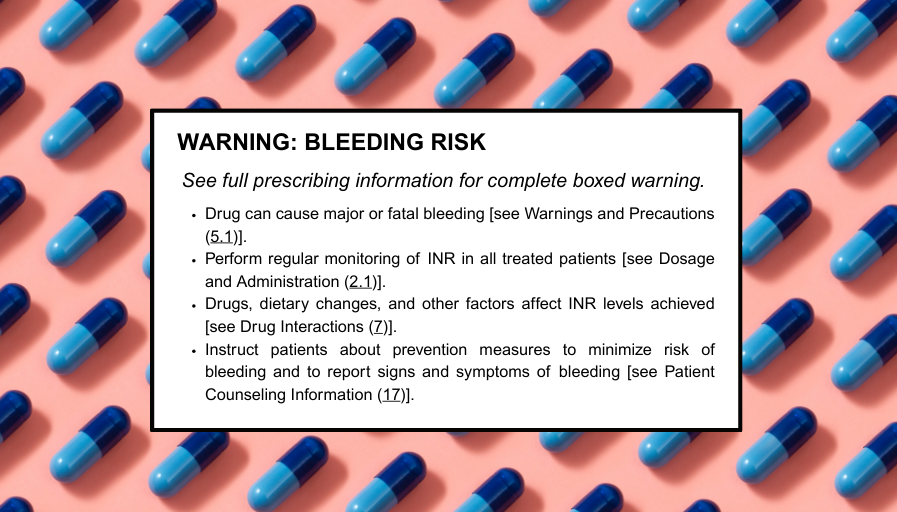

GMP stands for Good Manufacturing Practice. These are the regulations that govern how drugs must be manufactured to ensure quality and patient safety. In the U.S., they’re enforced by the FDA and codified in 21 CFR Parts 210 and 211 (for drugs).

GMP covers:

- Personnel training

- Cleanroom standards

- Documentation practices

- Equipment validation

- Batch records

- Deviation management

- Quality systems

- Change control

GMP answers a different question: Are you manufacturing your product under controlled, compliant conditions? If CMC is the blueprint, GMP is the rulebook.

Differences

| CMC | GMP |

| Part of your regulatory submission | Ongoing regulatory requirement |

| Product-specific | Facility and system-wide |

| Focuses on how your drug is made and tested | Focuses on how your facility operates |

| Submitted to regulators | Inspected by regulators |

Another way to think about it:

- CMC = What you say you do

- GMP = What you actually do (and can prove)

Why It Matters

You can have a brilliant molecule. You can even have perfect clinical data. But if your CMC package is weak, regulators won’t approve you. And if your GMP systems fail, regulators will shut you down.

Bottom Line

CMC builds the scientific case that your product can be consistently made. GMP ensures you’re actually doing it correctly—every batch, every day. In biotech, science gets you noticed. Manufacturing quality gets you approved.

Biotech Primer is your go-to source for interactive training across the biotechnology, pharmaceutical, molecular diagnostics, and medical device sectors. Explore a range of in-depth biotech courses designed to deepen your understanding of key principles and applications in the field.

Learn More